The Single Strategy To Use For Sandblasting

Wiki Article

The Main Principles Of Sandblasting Adalah

Table of ContentsSandblasting And Powder Coating - The Facts10 Simple Techniques For Sandblasting And Painting Near MeSee This Report about Sandblasting And PaintingEverything about Sandblasting And Powder CoatingSandblasting Air Compressor Can Be Fun For EveryoneThe Main Principles Of Sandblasting And Painting Near Me

Recognized as abrasive blasting, sandblasting is a surface ending up procedure that involves the use of a powered equipment generally an air compressor as well as a sandblasting equipment to spray rough particles under high pressure against a surface area. It's called "sandblasting" due to the fact that it blasts the surface with bits of sand.In this article, you'll discover more concerning this surface area ending up procedure and also just how it's done. Sandblasting leverages the unpleasant residential properties of sand to produce smoother surfaces with less physical flaws and flaws. It's clear that sand is harsh and also abrasive. Since of these homes, it has the ability to deteriorate at excess or unwanted product on a surface.

When massaged against a surface area, the sand removes some of the top-layer product, thus developing a smoother structure. Sandblasting functions the exact same method except it includes using highly pressurized sand. The very first step to carrying out sandblasting is putting the sand into the sandblasting machine. Sandblasting equipments have a chamber on top in which the sand is put.

Examine This Report about Sandblasting Alternatives

The procedure gets rid of several of the excess product on the concrete, which in turn makes it smoother. Sandblasting is just one of numerous blasting-type surface area ending up processes. There's likewise shot blasting, which is much more effective at smoothing or else rough as well as inflexible surface areas - sandblasting and powder coating. What's the difference between sandblasting and shot blowing up exactly? With sandblasting, sand is pushed versus a surface area.

The balls or beads are frequently made of stainless steel, copper, light weight aluminum or zinc. No matter, all of these metals are more difficult than sand, making shot blasting also extra effective than its sandblasting equivalent. No tags for this post.

Some Ideas on Sandblasting Air Compressor You Should Know

Sandblasting is a fantastic method to get rid of corrosion or paint from a product. By making use of an abrasive medium and pressurized air, a sandblaster promptly cleans up a surface and leaves it like new. Before start, you require to make certain you grab the ideal abrasive material as well as know how to safely utilize a blaster.

Not known Details About Sandblasting Air Compressor

Process speeds are usually not as quick as standard completely dry abrasive blasting when making use of the comparable dimension and sort of media, in component because the existence of water in between the media as well as the substrate being refined produces a lubricating cushion that can protect both the surface area and also the media, reducing malfunction prices.Wet blasting of light steel will result in immediate or 'flash' deterioration of the blown up steel substrate due to the existence of water. The lack of surface area recontamination additionally allows the usage of solitary devices for numerous blowing up operationse.

This process is even milder than wet blowing up, allowing mating surface areas to be cleaned while keeping their capability to mate. Grain blowing up paint from a concrete curb.

The Best Guide To Sandblasting And Painting Near Me

It is used to tidy calcium down payments from pool ceramic tiles or any type of other surface areas, remove embedded fungus, as well as lighten up grout color. It is also used in vehicle body job to get rid of paint. In eliminating paint for automobile body work, bead blasting is favored over sand blasting, as sand blasting has a have a peek at this site tendency to create a higher surface profile than grain blasting.

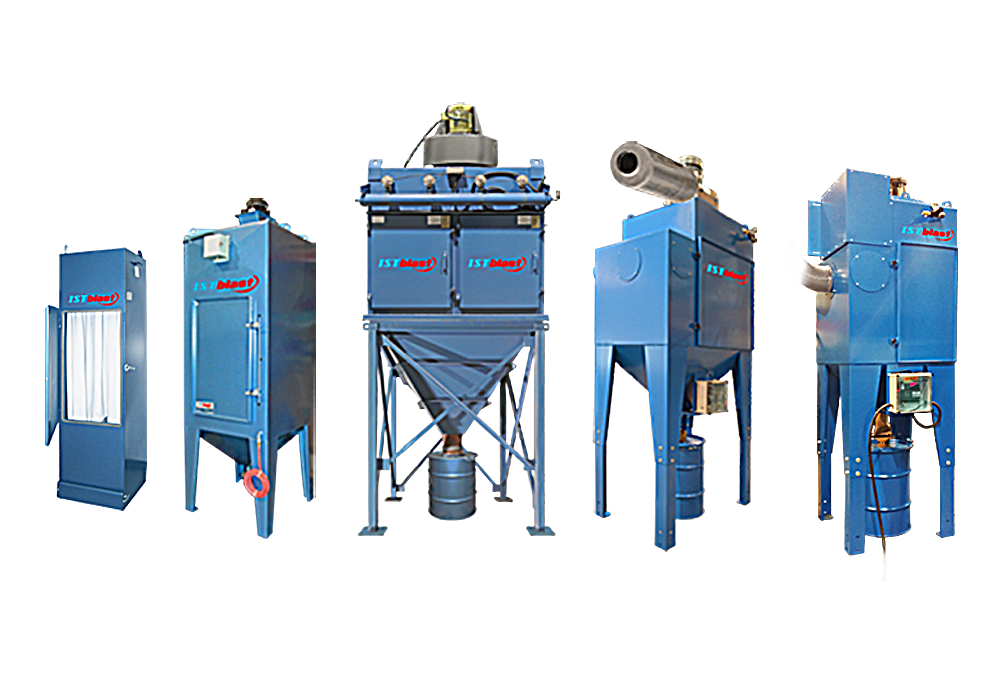

Specialized wheel blast machines move plastic abrasive in a cryogenic chamber, and is normally used for deflashing plastic and rubber components. The size of the wheel blast equipment, as well as the number and power of the wheels vary significantly depending on the components to be blasted as well as on the anticipated outcome and efficiency. sandblasting machine.

The smart Trick of Sandblasting That Nobody is Discussing

Either the nozzle or component can be relocated automated procedure. Automated blasting is simply the automation of the unpleasant blasting procedure. Automated blowing up is often simply an action in a larger automated treatment, normally entailing various other surface area treatments such as preparation as well as finish applications. Treatment is commonly required to isolate the blowing up chamber from mechanical components that might be subject to dust fouling.Gadget made use of for including sand to the pressed air (top of which is a screen for adding the sand) Mobile dry abrasive blast sandblasting enclosure systems are commonly powered by a diesel air compressor. The air compressor gives a huge quantity of high pressure air to a single or numerous "blast pots".

Report this wiki page